Heat-resistant rods

| TYPE | 4724 | 4742 | 4746 | 4762 | 4828 | 4841 |

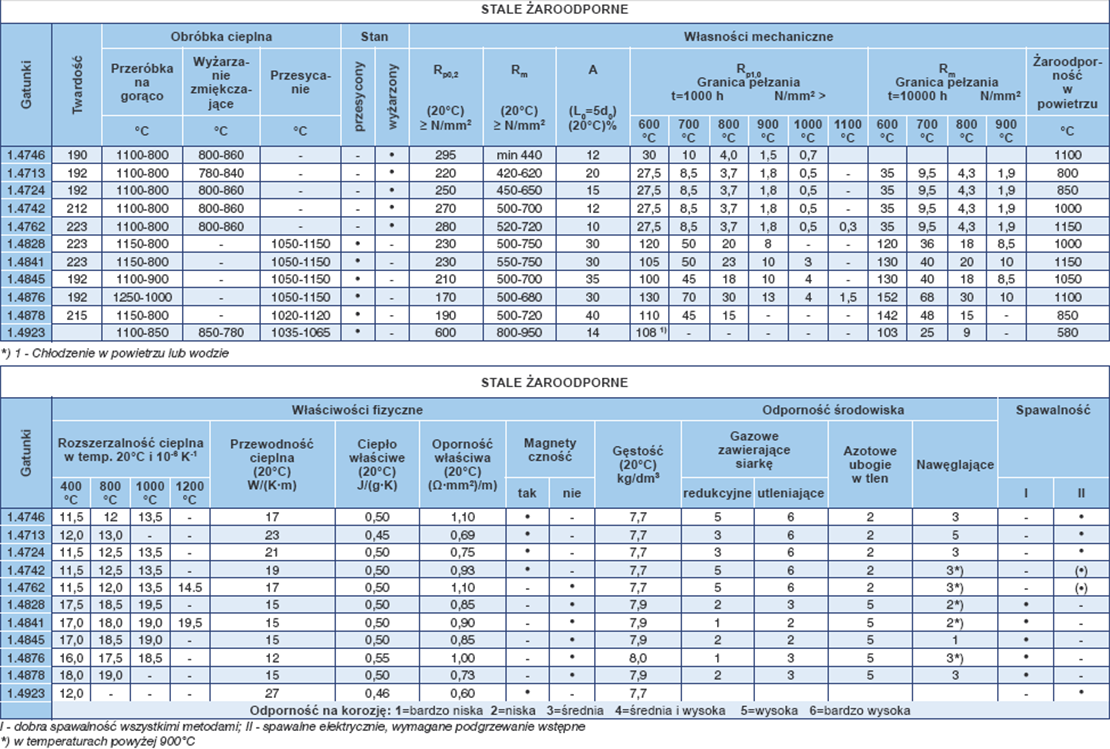

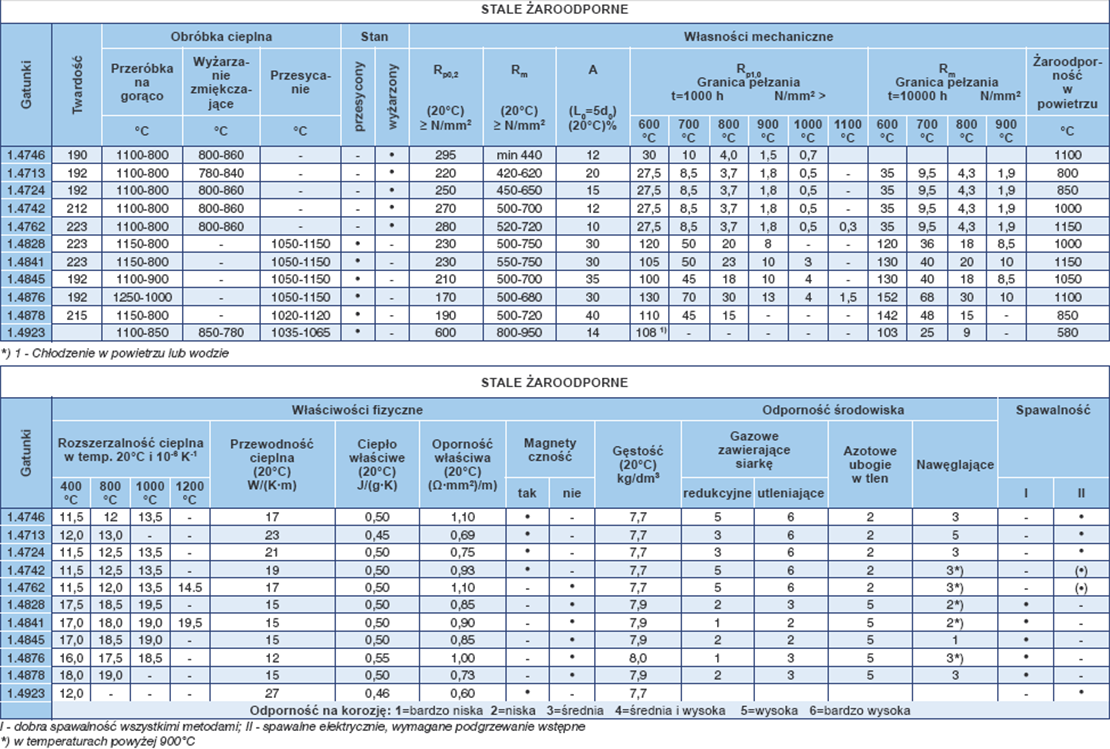

PARAMETERS OF INDIVIDUAL TYPES OF STEEL

Services

Transport

Plasma torch cutting

Our offer includes sheet metal, rods, flat bars and formats in the following grades:

1.4713 , 1.4724 , 1.4742 , 1.4746 , 1.4749 , 1.4762 , 1.4828 , 1.4841 , 1.4878

Thickness of sheets : od 0,8 mm do 40 mm

Standard sheets : od 1000 x 2000 do 2000 x 6000

custom sizes cut to order

Diameters of rods: od 8 mm do 100 mm

Lengths of rods: od 3 mb do 6 mb

Custom lengths cut to order

Heat-resistant steel is a material characterized by excellent resistance to oxidizing gases at high temperatures, which lead to corrosion. This property causes that it is used for the production of various types of industrial furnaces and steam boilers, fans, rails, hubcaps and transport elements, and so in those devices and products whose operation is associated with difficult conditions in the temperature range. Depending on the chemical composition, for example, chromium or chromium-nickel steels can be distinguished, but the classification of these steels is more widespread due to their structure. Distinguish here are ferritic, ferritic-perlitic, ferritic-austenitic and austenitic steels.

Steel used for load-bearing parts, components and parts, devices operating at low loads. Resistant to sulfur compounds, heat resistant steel up to 800 ° C

600°C - creep limit R1/1000 ,MPa - 20

700°C - creep limit R1/1000 ,MPa - 5

800°C - creep limit R1/1000 ,MPa - 1

Density - 7,70 (g*cm3 )

Heat capacity Cp 20-100oC - 500 ( J*kg-1 * K-1)

Thermal conductivity λ - 35,60 (W*m-1 * K-1)

Linear expansion coefficient α20-100°C - 11,0*10-6 (K-1)

Steel with a ferritic structure, resistant to gases containing sulfur compounds and reducing gases, poorly resistant to the effects of carburizing, nitriding and nitrocarburizing atmosphere, intended for heat-resistant parts of industrial boilers and furnaces, vacuum chambers, etc. Heat-resistant in the air up to 950 ° C

600°C - creep limit R1/1000 ,MPa - 34, creep strength Rz/10000 ,MPa - 29, creep strength Rz/100000 ,MPa - 13,2

700°C - creep limit R1/1000 ,MPa - 10, creep strength Rz/10000 ,MPa - 8, creep strength Rz/100000 ,MPa - 3,7

800°C - creep limit R1/1000 ,MPa - 4, creep strength Rz/10000 ,MPa - 3, creep strength Rz/100000 ,MPa - 1,3

900°C - creep limit R1/1000 ,MPa - 1,5, creep strength Rz/10000 ,MPa - 1,5, creep strength Rz/100000 ,MPa - 0,6

Modulus of elasticity E 206 GPa

hammering - 1100-800°C

Rolling 1100-800°C

Softening annealing – 800-850°C

Ferritic refractory steel, resistant to gases containing sulfur compounds and reducing gases, poorly resistant to the carburizing, nitriding and nitrocarburizing atmosphere, designed for heat-resistant parts of industrial boilers and furnaces, vacuum chambers, etc. Heat resistant steel up to 1050 ° C.

Density - 7,60 (g*cm3 )

Heat capacity Cp 20-100oC - 500 ( J*kg-1 * K-1 )

Thermal conductivity λ - 16,80 (W*m-1 * K-1 )

Linear expansion coefficient α20-100°C - 10,0*10-6 ( K-1 )

Modulus of elasticity E 196 GPa

hammering 1050-600°C

Rolling 1050-600°C

Softening annealing – 850-900°C

Steel in the H25T grade is ferritic steel, it is very resistant to oxidation, in oxidizing atmospheres it can be used up to 1150 ° C, while in reducing atmospheres, carburizing atmospheres and containing sulfur compounds up to 1000 ° C. With long-term operation at a temperature of 400 to 550 ° C, or slow cooling in this temperature range, and at normal temperature, the steel in this grade is very fragile. At higher temperatures above 550 ° C it is characterized by considerable ductility. This steel does not cure when cooled quickly from high temperatures and its structure can not be shredded by heat treatment, which results in difficulties in its welding. At work at temperatures above 950 ° C, grain growth occurs, and the addition of titanium to H25T steel is expected to counteract grain growth. This species has very high resistance to corrosive gases and can be used wherever high strength properties are not required at high temperatures.

Species used for the production of low-load parts of industrial furnaces, tools for the glass industry, porcelain firing baskets, thermocouple covers, parts of sulfur distillation equipment, sulfur mine lines, rubber products factories and mineral oil refineries, parts of burners and soot blowers, parts heating back and hot gas pipes etc.

600°C - creep limit R1/1000 ,MPa - 29

700°C - creep limit R1/1000 ,MPa - 10

800°C - creep limit R1/1000 ,MPa - 4

900°C - creep limit R1/1000 ,MPa - 1,5

1000°C - creep limit R1/1000 ,MPa - 0,7

Density - 7,70 (g*cm3 )

Heat capacity Cp 20-100°C - 500 ( J*kg-1 * K-1 )

Thermal conductivity λ - 16,80 (W*m-1 * K-1 )

20 - 100°C 10,1 ∙ 10-6 1/°C

20 - 200°C 10,7 ∙ 10-6 1/°C

20 - 300°C 11,0 ∙ 10-6 1/°C

20 - 400°C 11,2 ∙ 10-6 1/°C

20 - 500°C 11,3 ∙ 10-6 1/°C

20 - 600°C 11,4 ∙ 10-6 1/°C

20 - 700°C 11,7 ∙ 10-6 1/°C

20 - 800°C 12,2 ∙ 10-6 1/°C

20 - 900°C 12,7 ∙ 10-6 1/°C

20 - 1000°C 13,4 ∙ 10-6 1/°C

Hardness max 220 HB

Modulus of elasticity E 206 GPa

Steel in the H25T grade is a hard-weldable steel, requires the use of special welding technology, required heating before and during welding from 200 to 400 ° C. After welding, annealing should be carried out at a temperature of 750 - 800 ° C and then cooled in air or water. The addition of titanium in the amount of 0.8 - 0.9% is used to stabilize the coal, which at the same time improves the weldability.

hammering - 1100-800°C - heat slowly to 850 ° C and then quickly to the temperature of forging softening 750-800°C - After forging, cool in ashes Steel after a properly conducted heat treatment has a ferritic structure.

H25T grade or equivalent (15X25T, 1.4746, 1.4749, X18CrN28, X8CrTi25) we offer: heat-resistant seamless hot-rolled tubes, seamless tubes cold drawn, rolled bars, forged bars, flat bars, heat-resistant sheets (cold rolled and hot rolled), and forged forgings.

Steel in grade H20N12S2 / 1.4828 is austenitic steel intended for the production of heavily loaded parts operating at high temperatures, heat-resistant in the air up to a temperature of about 1050 ° C, resistant to atmospheric carburizing, nitriding and nitrocarburizing. The grade of this steel is not very resistant to gases that contain sulfur compounds. Weldable steel, heating during welding and heat treatment after welding are not required. Forging at 1150 ° C - 900 ° C, supersaturation at 1050 ° C - 1100 ° C, cooling in water, products up to 2 mm thick should be cooled in air.

600°C - creep strength Rz/10000 ,MPa - 118, creep strength Rz/100000 ,MPa - 71

700°C - creep strength Rz/10000 ,MPa - 44, creep strength Rz/100000 ,MPa - 23

800°C - creep strength Rz/10000 ,MPa - 18, creep strength Rz/100000 ,MPa - 7

900°C - creep strength Rz/10000 ,MPa - 7, creep strength Rz/100000 ,MPa - 2

1000°C - creep strength Rz/10000 ,MPa - 1,5 , creep strength Rz/100000 ,MPa - 0,3

Density - 7,80 (g*cm3 )

Heat capacity Cp 20-100°C - 500 ( J*kg-1 * K-1 )

Thermal conductivity λ - 14,70 (W*m-1 * K-1 )

Linear expansion coefficient α20-100°C - 15,0*10-6 ( K-1 )

Modulus of elasticity E 196 GPa

hammering - 1150-950°C - After forging, cool in the air

Rolling 1150-950°C -

supersaturation 1100-1150°C - cool in water

Austenitic heat resistant steel used for the production of heavily loaded parts of devices operating at high temperatures resistant to nitriding, carburizing, carbonitriding, poorly resistant to gases containing sulfur compounds. Heat-resistant steel in the air up to 1150 ° C, heat-resistant up to about 700 ° C.

600°C - creep limit R1/1000 ,MPa - 98, creep strength Rz/10000 ,MPa - 118, creep strength Rz/100000 ,MPa - 71

700°C - creep limit R1/1000 ,MPa - 44, creep strength Rz/10000 ,MPa - 39, creep strength Rz/100000 ,MPa - 18

800°C - creep limit R1/1000 ,MPa - 20, creep strength Rz/10000 ,MPa - 18, creep strength Rz/100000 ,MPa - 7

900°C - creep limit R1/1000 ,MPa - 9, creep strength Rz/10000 ,MPa - 7, creep strength Rz/100000 ,MPa - 2,5

1000°C - creep limit R1/1000 ,MPa - 4, creep strength Rz/10000 ,MPa - 1,5 , creep strength Rz/100000 ,MPa - 0,3

1100°C - creep limit R1/1000 ,MPa - 1,5 , creep strength Rz/10000 ,MPa - - , creep strength Rz/100000 ,MPa - -

1200°C - creep limit R1/1000 ,MPa - 0,5 , creep strength Rz/10000 ,MPa - - , creep strength Rz/100000 ,MPa - -

Density - 7,80 (g*cm3 ) Heat capacity Cp 20-100°C - 500 ( J*kg-1 * K-1 ) Thermal conductivity λ - 14,70 (W*m-1 * K-1 ) Linear expansion coefficient α20-100°C - 15,0*10-6 ( K-1 )

Steel 1.4841, X15CrNiSi25-20, AISI 314, AISI 310S, AISI 310, are most commonly arc welded with coated electrodes, submerged arc as well as in argon and helium gases. These materials do not need preheating before welding - thin electrodes should be used to minimize the heat supply. The grade of welding does not require any calving unless the welded components are to work in an environment causing intergranular corrosion, i.e. in acidic condensate environments. In this case, welded parts should be annealed for 10-30 minutes at 1050 - 1100 ° C, and then cooled in water or air (depending on the thickness of the welded parts). The use of gas welding or CO2 shielding is not recommended

Modulus of elasticity E 196 GPa

hammering - 1150-800°C - After forging, cool in the air

supersaturation 1050-1100°C - cool in water

TYPES OF SURFACE FINISHING

| SYMBOL | Circumstances | SURFACE FINISHING | description |

| 1D | Hot rolled, heat treated, pickled | Free of scale | Usually standard for most steel grades; also common finish for further processing. |

| 1C | Hot rolled, heat treated, not descaled | Covered with rolling scale | Suitable for parts which will be descaled or machined in subsequent production or for certain heat- resisting applications. |

| 1C (HOT) | Hot rolled, heat treated, not descaled | Covered with rolling scale | Suitable for parts which will be descaled or machined in subsequent production or for certain heat- resisting applications. |

| 2C (COLD) | Cold rolled, heat treated, not descaled | Smooth with scale from heat treatment | Suitable for parts which will be descaled or machined in subsequent production or for certain heat- resisting applications. |

| TYPE | 4724 | 4742 | 4746 | 4762 | 4828 | 4841 |

PARAMETERS OF INDIVIDUAL TYPES OF STEEL

Plasma torch cutting